Condensation Resistance in Healthcare Facilities: The Pivotal Role of Fibreglass-Framed Curtain Walls

September 1, 2023

There’s a critical issue at the crossroads of healthcare design and facilities maintenance: condensation!

Long a focus in cold climate architectural practice, the urgency to address condensation concerns has only increased with renewed attention towards extreme climate events as well as public health lessons learned from the recent pandemic. So when the exterior temperature drops to -18ºC (0ºF) — as it does in most of Canada and much of Northeastern United States — how can we maintain the required indoor relative humidity (RH) of 50% without risking window or curtain wall condensation?

Understanding The Risks:

Humidity and Condensation

Professionals designing high-humidity buildings such as hospitals and other healthcare facilities in these cold climates have long wrestled with the challenge of preventing window and curtain wall condensation. Facilities such as acute care, long-term care, and urgent care centres, along with some labs that necessitate high-humidity are particularly prone to condensation, but what can we do when typical aluminum-framed double-glazed facades are insufficient to the task?

Various strategies have been developed to work around this clear and present issue, including reducing humidity levels (even though this is detrimental to patient wellbeing) as well as increasing heat and air flow at the perimeter (even though this increases maintenance costs and makes the space drafty for patients), both with only limited success due to the associated health and environmental risks.

In the wake of the recent pandemic, infection control has gained prominence, leading to recommendations for higher humidity environments for many institutional facilities, especially in healthcare. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), and even infection control consultant at Harvard Medical School, Dr. Stephanie Taylor, recommend maintaining RH between 40% to 60% for optimal human health in healthcare settings. This range, often dubbed the ‘Goldilocks’ zone, is neither too dry nor too moist, and reduces the ability of pathogens like COVID-19 from replicating and transmitting.

Unfortunately for typical building envelopes, this trend towards increased RH also increases the risk of condensation on windows and curtain wall systems, particularly in cold climates. Fortunately, Thermaframe is here to help!

Evaluating Condensation Performance

The performance of condensation resistance can primarily be gauged using two key metrics: Condensation Resistance Factor (CRF) and Condensation Resistance (CR). While these produce directly incomparable scores, both are useful in their respective applications.

Condensation risk for glazing systems is explained as occurring when the temperature of the glass or framing material drops to the dew point temperature of the interior space. This phenomenon can lead to water formation on the glass or framing surface, damaging the seals that would otherwise prevent air infiltration and exfiltration, and keep interior air free from external microbes and pollutants. Given the sensitive populations in healthcare facilities, these long-term risks are critical to understand and manage during the design process.

Better Building Materials Reduce Condensation Risk

In recent lab tests, GlasCurtain’s Thermaframe systems have truly outdone themselves. Picture this: at -18ºC (0ºF), this next-generation fibreglass-framed system remains above the dew point even at interior relative humidity (RH) levels of 50%. Things get even cooler (pun intended) in the face of an even more frigid -30ºC (-22ºF) temperatures, where Thermaframe systems remain above the dew point at an impressive 35% RH.

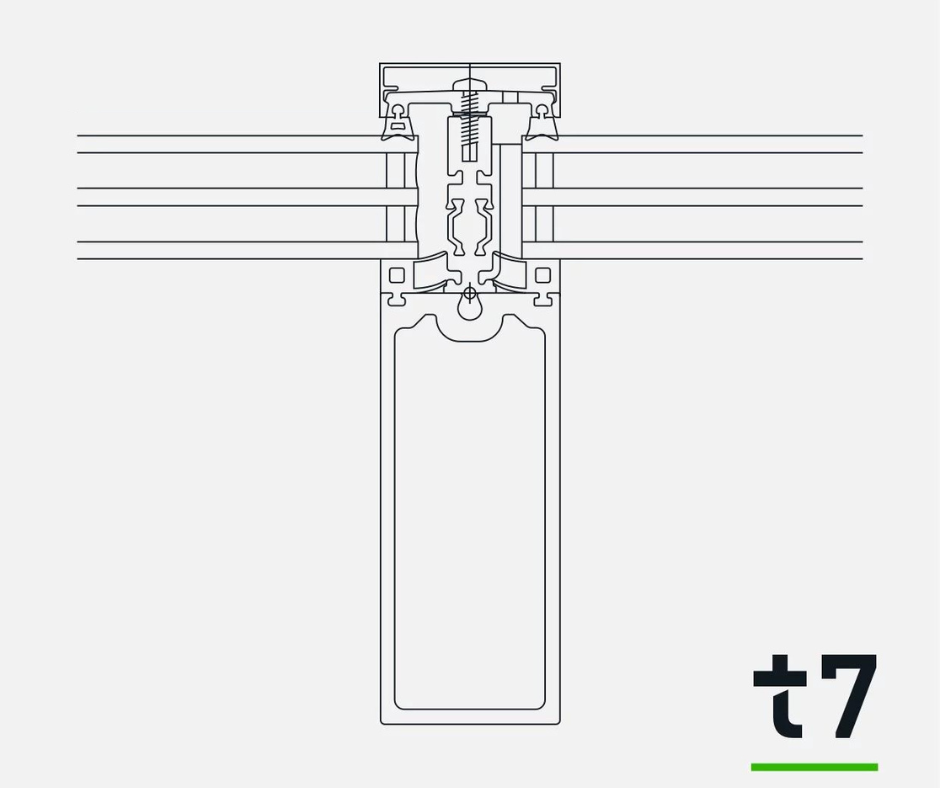

The future of healthcare facilities with optimal RH necessitates innovative approaches to conserve energy, increase the durability of building envelope components, and minimize condensation risk in order to preserve capital investment and enhance patient outcomes. This is why Thermaframe systems are increasingly in demand for healthcare facilities, including the new Whitehorse General Hospital expansion project in Yukon, Canada, which is currently under construction using Thermaframe 7. Northern Front Studio and Thinkspace Architecture were chosen to provide design services for the new mental health unit. Renderings by project architect Northern Front Studio are seen below (exterior) and at the top of this post (interior).

Fibreglass: The Future of Condensation Management

Thermaframe fibreglass-framed systems offer four (4) major advantages for cold climate healthcare facilities looking to reduce condensation risk:

- Best-in-Class Condensation Resistance: In verified laboratory tests, Thermaframe systems saw no condensation at -18ºC (0ºF) with 50% interior RH and at -30ºC (-22ºF) with 35% interior RH.

- Industry-leading R-values: Thermaframe systems range from R7 to R9, which is at 2-3x the performance value of conventional aluminum-framed systems, making fibreglass-framed system less prone to reaching temperatures below the dew point, where condensation occurs.

- Corrosion Resistance: Unlike aluminum, which needs an anodizing process to achieve corrosion resistance, fibreglass is inherently corrosion-resistant, making it ideal for high-humidity environments such as healthcare facilities.

- Thermal Stability: The superb thermal performance of fibreglass framing and triple-glazing also translates to reduced expansion and contraction of critical building envelope materials such as seals and gaskets. This improves the longevity of the facade while also improving the longevity of mechanical ventilation systems.

Overall, the forward-thinking use of Thermaframe systems marks a significant leap forward in reducing condensation risk in healthcare facilities, particularly in cold climates. As healthcare design evolves for the 21st century and beyond, architects, designers, building owners and operators are looking for high-performance and low-carbon solutions to these all-too-common issues.

With over 10 years of commercial production and a continuous track record of success, Thermaframe is here to help with your next cold climate healthcare facility!

To learn more CONTACT US today