Where Does Reusability Fit In?

April 24, 2023

The Forgotten Third “R”

Architecture is more than just buildings. It’s an expression of culture, society, and the values that define our collective aspirations. Yet, the way we’ve been designing and constructing buildings – especially in the last few generations – has unfortunately neglected the very environment in which we live.

For instance, one of the most iconic structures in the world, the Empire State Building, required the demolition of another well-maintained and fully-functioning building, the Waldorf-Astoria Hotel. This not only resulted in the loss of a remarkable piece of architecture and its associated history, but also an incredible amount of waste and energy consumption that surely could’ve been avoided. Beyond its iconic status, the Empire State Building is also then a stark reminder of the inherent fear of obsolescence that’s subconsciously embedded in modern construction practices

In an era where buildings are seemingly torn down and replaced at an ever-accelerating pace, we must ask ourselves the question: how long can this unsustainable cycle of “out with the old, in with the new” continue? And what are the consequences of our actions in pursuit of the built environment of our dreams?

In this blog post, we’ll explore the benefits of reusable building materials for long-term sustainability. We’ll also present the optimistic case for a world in which material reuse lowers energy consumption while also bringing vitality to our communities. Lastly, we’ll take a closer look at GlasCurtain’s contribution to long-term sustainability by discussing how our Thermaframe fibreglass-framed curtain wall systems facilitate material reuse.

The Paradox of Progress

With approximately 1.0 billion annual tonnes of construction and demolition waste in the European Union alone (archived) – and closer to 7x that amount of waste globally each year – the construction industry stands as one of the world’s foremost waste generators. This makes intuitive sense given the current rate at which older buildings are torn down and new ones are erected. Indeed, the excessively short lifespans of the majority of buildings has resulted in staggering amounts of raw material extraction, environmental degradation, and carbon emissions. But does it have to be that way?

By specifying high-quality, low-embodied-carbon systems like Thermaframe fibreglass-framed curtain walls, a building’s lifespan can be significantly extended and its materials can even be thoughtfully reused at end-of-life. However, without the implementation of holistically-framed material reuse provisions, short-term choices are often made, leading to the selection of low-quality materials and products that cannot be repurposed or reused. There is therefore a pressing need for more sustainable approaches (archived) to construction and demolition, where long-term considerations are given priority over short-term expediency.

Beyond the Bulldozer

“Value-engineering” (aka. watering/dumbing-down designs with lower-quality building materials) leads to buildings that deteriorate and require replacement much sooner than high-quality buildings. Moreover, these “value-engineered”/low-quality buildings are frequently less recoverable or reusable for future projects, necessitating their disposal in environmentally damaging ways. As such, high-quality materials play a clear role in delivering long-term sustainability of the built environment, reducing its environmental impact, and ensuring the longevity of our cultural investments.

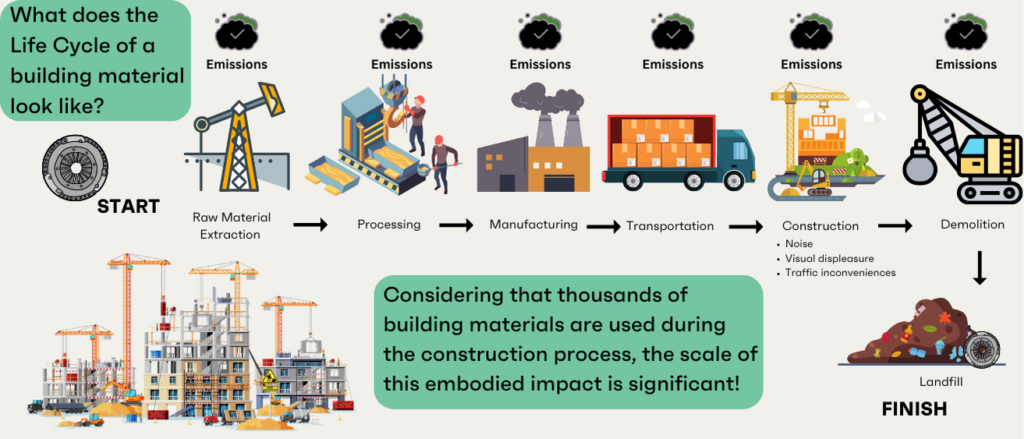

Now let’s take a closer look at the lifecycle of a single building material, how it comes into being, and some of the environmental impacts along the way:

- Raw material extraction: Raw materials are mined or otherwise extracted from the earth, which is a polluting and carbon-intensive process, one often located in some of the most ecologically sensitive regions in the world.

- Processing: Raw materials are transformed into intermediate or final products, which can involve mechanical, chemical, thermal, or electrical processes, each involving varying degrees of environmental impact depending on the specific material.

- Manufacturing: Processed material is then transported to a manufacturing (and potentially further still to a fabrication facility) where machinery, emitting more carbon, is used to create the final product that will be installed on-site.

- Transportation: Once the final product is complete, it is transported again to the installation site, where it may be further assembled.

- Construction: When new buildings are ready for construction, any old buildings on the site are demolished and mostly sent straight to the landfill, despite many of the materials being in perfectly serviceable or reusable condition.

Much of this impact can be minimized! Some, of course, cannot and is simply “baked in the cake” of the building materials we use. But given that there’s a baseline amount of environmental impact embodied in the manufacturing of new building materials, it serves the conscientiousness among us to recall the third “R” of “Recycle, Reduce, Reuse” and not just the first two. The lifecycle of a single building material, from its extraction as raw material to its disposal as waste after a relatively short period of use, illustrates the possible scale of waste when we don’t reuse building materials, especially when we multiply the processes outlined above by the thousands and thousands of materials and products used in each new building.

Really, it should be evident that the all-too-common approach of low-quality construction and subsequent demolition is unsustainable and comes with significant environmental costs, so isn’t it time to adopt better deconstruction practices and to specify building materials with reusability in mind?

Building Better

The material reuse process is an interdisciplinary approach that draws from fields including construction, structural design, construction management, and industrial ecology. It encompasses two distinct phases per André Thomsen of Delft University of Technology et al. :

Phase 1: Careful and highly controlled planning that results in a material reuse process with identifiable components and materials.

Phase 2: Continued use of deconstructed components and materials in other buildings or functions, with the goal of avoiding landfills.

Material reuse isn’t just better for the environment, it’s better for everything! It reduces the need for virgin materials, saving manufacturing energy, and minimizes waste sent to landfills. Salvageable materials in good condition can significantly reduce a building’s carbon footprint by eliminating emissions associated with extraction, manufacturing, transportation, and disposal, while also giving new buildings a crucial connection to our shared history.

Thankfully, there are a few noteworthy creatives in the world – such as Tokyo-based Hiroshi Nakamura & NAP – who are reusing building materials in inspiring ways. By recycling windows for the Kamkatz Public House, for example, a distinctive and sustainable solution was arrived at for this unique facade. Such practices not only contribute towards environmental conservation, but also result in aesthetically stunning structures that leave a lasting impression and connect to the history of a place. It’s a win-win-win!

Unfortunately, case studies like this are far too rare, but improvements to community awareness, public policy, industry incentives, and research are essential to our future. To borrow a meme, it’s not just Japan living in the year 2050 — it will soon be all western developed nations. The future of our planet depends on it.

GlasCurtain and Reusability

So where does GlasCurtain fit in? For starters, Thermaframe curtain wall systems are all stick-built (site-glazed), utilizing pressure plates and caps for added flexibility and simplified deconstruction compared to unitized systems with split frames/four-sided structural silicone glazing. Stick-built systems make the material reuse process much more feasible because it’s primarily mechanical connections adhering components to one another, which are more reversible than chemical connections. Overall, reusability is essentially impossible without deconstructability, so this benefit of Thermaframe stick-built systems goes a long way towards improving the environmental profile of this key building system for future generations.

Additionally, Thermaframe systems are recyclable, low-carbon, extremely durable, and much less susceptible to corrosion than aluminum, particularly in high-humidity environments like healthcare facilities or many industrial applications.

Bringing it all together

- Building materials have a very high embodied (upfront) environmental cost

- We want to use high-quality materials wherever possible

- We want to reuse building materials wherever possible

- Thermaframe stick-built curtain wall systems are great for reusability!

Reusing building materials may seem far-fetched in our wasteful consumerist culture today, but if we don’t plant the seeds of sustainability now, how can we expect them to grow in the future?

Let’s not forget the third “R”!

Learn More

Interested in learning more about material reuse and deconstruction? Check out these sources:

- Video: Designing for Deconstruction | Pt. 1 | Setting the Scene

- Video: Designing for Deconstruction | Pt. 2 | Experimental Methods

- Blog Post: The Do’s and Don’ts for Deconstructability, written by UK Green Building Council (UKGBC) Sustainability Advisor Kai Liebetanz

[Image Credits: EuroInnova, Cornell University, ServPro, GlasCurtain, Bernd Schmidt, Nacasa and Partners Inc, GlasCurtain]